Towards a circular economy

Researchers from Wageningen University & Research (WUR) offer technical and administrative support to companies in the chemical, fashion, agricultural and food production sectors that want to work in a circular way. They help companies with questions specific to their branch, like a home furnishing centre that wants to reuse packaging waste but is finding that hard to do. Scientists from WUR take a look at how companies and municipalities can concretely address these types of issues. We are still at the dawn of a circular economy, so research and solutions are desperately needed. Which issues do you feel require a circular solution?

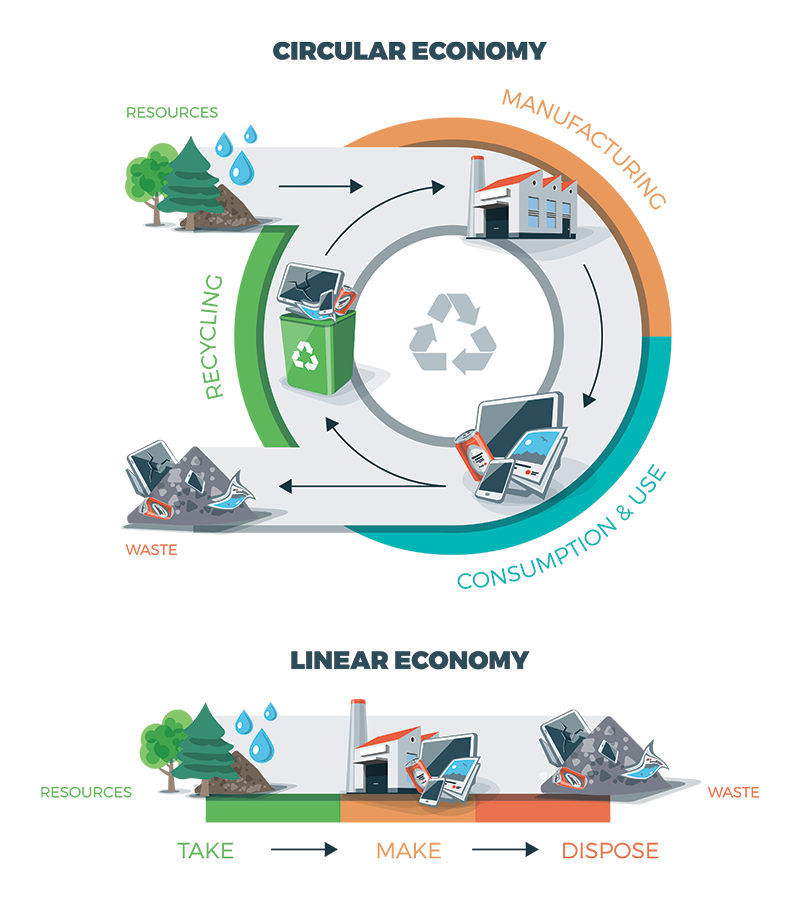

‘The circular economy is quite difficult to understand, but it boils down to closing the cycles in the most sustainable way possible,’ explains researcher Wim de Haas. ‘A simple example is that you throw potato peels onto the compost heap in the garden and then use the compost for your vegetable garden. Here, waste is used as a raw material.’ Researchers from Wageningen are working towards circular solutions in different fields. For example, valuable nutrients can be extracted from manure and the chemical industry can extract raw materials from agricultural waste streams and kitchen and garden waste, and no longer relies exclusively on petroleum. Even the fashion industry is also working more conscientiously on recycling. Another great example of circular solutions is the circular agrofood system.

‘The circular economy is quite difficult to understand, but it boils down to closing the cycles in the most sustainable way possible,’ explains researcher Wim de Haas. ‘A simple example is that you throw potato peels onto the compost heap in the garden and then use the compost for your vegetable garden. Here, waste is used as a raw material.’ Researchers from Wageningen are working towards circular solutions in different fields. For example, valuable nutrients can be extracted from manure and the chemical industry can extract raw materials from agricultural waste streams and kitchen and garden waste, and no longer relies exclusively on petroleum. Even the fashion industry is also working more conscientiously on recycling. Another great example of circular solutions is the circular agrofood system.

Increasing urgency

‘Many resources are finite and will become scarcer and more expensive or are only found in countries on which you don’t want to be dependent. Producing new raw materials from waste streams is, therefore, a good idea for both financial and geopolitical reasons,’ explains De Haas. A circular economy is also beneficial for the preservation of biodiversity and nature, because less harmful waste ends up in the environment while reducing greenhouse gas emissions will help mitigate climate change. ‘It is therefore becoming increasingly urgent to design the economy in a circular way.

Despite this urgency, the circular economy in the Netherlands is still in its early stages. Last year, companies, civil society organisations and governmental authorities drew up agendas for the ‘Grondstoffenakkoord’ (national agreement on raw materials) for a circular economy in the Netherlands by 2050′. ‘However, the government doesn’t set any clear targets in this agreement. The objectives of the energy transition are very clear, while those of the circular transition have yet to be explicitly formulated,’ says De Haas.

“You now see that companies are renting or leasing products to clients or consumers or charge a deposit for them more frequently. An example of this a is bed manufacturer, who makes the mattresses in such a way that the materials can be reused.”

Taking the initiative

Some large companies are developing circular technology, redesigning production processes and devising new business models. Discarded goods and electrical appliances are usually recycled, with a lot of raw materials being lost in the process. ‘It would be better if old washing machines and computers were returned to the manufacturer, who can recycle parts for new washing machines and computers,’ explains De Haas. ‘You now see that companies are renting or leasing products to clients or consumers or charge a deposit for them more frequently. An example of this is bed manufacturer Auping, who makes the mattresses in such a way that the materials can be reused. Companies like these are taking the initiative and have been awarded with prizes for their contribution to a circular economy as a result. However, there aren’t many good examples of circular practices yet,’ says the researcher.

Discarded goods and electrical appliances are usually recycled, with a lot of raw materials being lost in the process.

Garden furniture made from old plastic

At what level can the cycle best be closed? At the level of a company, district, municipality, region, province, country, Europe, the world? That depends on the particular situation. Circularity within companies is obvious, but regions are just as capable of being circular. However, this type of cooperation is more difficult to organise, and that is exactly what De Haas is working on. He is currently involved in a project in the Arnhem-Nijmegen region with three business parks that want to use packaging waste to good effect by processing plastic into garden furniture. ‘But you immediately run into practical problems,’ says De Haas. If canteens, restaurants and festivals all bought the same type of plastic, the processing would become much easier.’

“A change in thinking and behaviour is needed both within companies and among consumers. The government has a big responsibility in providing information and education about the circular economy.”

Obstructive regulations

Companies that form part of a home furnishing centre in the province of Gelderland want to reuse polystyrene foam, which is technologically easy to process. Before the polystyrene foam can be sent to a processing plant, it must be compressed in a special machine. When the companies use a pressing machine together, the company where the machine is located is seen as a waste processing company that needs different types of permits. ‘This is an obstructive regulation, even though processing polystyrene foam together is very profitable,’ notes De Haas. Together with the companies, municipalities and environmental services, he solves these kinds of problems.

Culture change

Major investments are needed to develop new models, partnerships and innovations. Nevertheless, De Haas expects the industry and production processes to be fundamentally restructured in twenty years’ time. ‘The biggest obstacle is the cultural change, the change in thinking and behaviour that is needed within companies and among consumers.’ Government has an important responsibility to provide information and education, which will ensure that the general public becomes familiar with the idea of the circular economy. In addition, government institutions should lead by example and enforce circularity in construction and infrastructure, as well as in their purchasing policies for, for example, office furniture.

‘Do we really have to have eighty different shampoos in the shop, buy new clothes each season and have a device or machine for every chore in the home?’

Overproduction

The most sustainable option is to avoid unnecessary production. ‘Do we really have to have eighty different shampoos in the shop, buy new clothes each season and have a device or machine for every chore in the home?’ asks De Haas. The government can curb overproduction by charging more VAT on goods and less VAT on services. ‘If repairing is cheaper and buying more expensive, people will have their broken things repaired rather than buying new ones. De Haas, however, does not think that we will be consuming substantially less in twenty years’ time. According to De Haas, social science-related research is needed to see which types of measures can help people to make better decisions. ‘The road to a circular economy is an evolutionary process in which WUR can assist in coming up with technical, economic and managerial solutions.’

Recommendations for circularity in regions

Recently the book Circulaire gebiedsontwikkeling. Bouwstenen voor governance van circulaire clusters (circular regional development: building blocks for the governance of circular clusters) by Wim de Haas and Remco Kranendonk was published. The two researchers at Wageningen Environmental Research describe their observations and experiences with circular development in three different areas and draw general lessons and offer advice. This handy booklet can be downloaded as a PDF file (available in Dutch only).

Read more:

- Longread Regional collaboration: investing in a circular economy

- Article about green chemistry

- Article about circular fashion

- Dossier circular agrofood system

- Download the book Circulaire gebiedsontwikkeling. Bouwstenen voor governance van circulaire clusters. (PDF, available in Dutch only)

- Read this blog in Dutch

What is being done in the field of circular phosphorous economy?